5-Axis CNC Universal Vertical Machining Centre - MIKRON HPM 1350U - 2008 /12

5-Axis CNC Universal Vertical Machining Centre - MIKRON HPM 1350U - 2008 /12

Location:Germany

Description

5-Axis CNC Universal Vertical Machining Centre

Manufacturer Mikron (Switzerland)

Model HPM 1350U

Year 2008/12

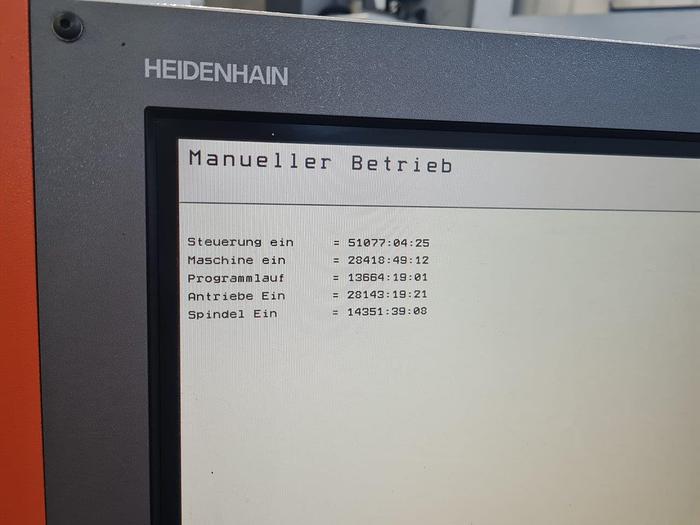

Control Heidenhain iTNC 530

NC-Rotary Table

Table diameter 1100 mm

Table loading capacity max. 1600 kg

Rotational axis C 360°

NC-Swivelling head

Tilting axis A +16° / -120°

Travels X 1350 mm

Y 1150 mm

Z 895/700 mm (Spindle Vertical/Horizontal)

Feedrates X,Y,Z 15000 mm/min

C 40 rpm

A 11 rpm

Rapids up to X,Y,Z 32000 mm/min.

C 40 rpm

B 20 rpm

Spindle motor rating 38 KW AC / 40%

Spindle speeds max. 15.000 rpm

Torque at the spindle max. 193 Nm

Tool taper HSK-A63

Tool magazine positions 46 station auto tool changer

Tool diameter

with/without adjacent tools max. mm

Tool length max. mm

Tool weight max. kg

Tool change time tool-to-tool sec

chip-to-chip sec

Machine weight approx. 14000 kg

Floor space requirements L x W, approx. 4890 x 4190 mm

Machine height approx. 2900 mm

Condition Very good condition

Equipment:

Complete equipment including toolholders, ICS, production package

Swiveling control

Swivel head with water-cooled direct drive

Head swivels horizontally/vertically

NC rotary table

NC swivel milling head

The measuring system is on the swivel axis

For maximum rigidity, the A-axis can be clamped in all positions on both sides.

The Mikron HPM 1350U is based on the traveling column principle.

A symmetrical table with no overhang directs the machining forces away - even with heavy loads.

The thermo-symmetrical structure guarantees long-term precision throughout the entire machining process.

For maximum precision: scraped contact surfaces for the guides.

The machine bed is cast out of one piece. It stands on three main feet.

High torsional rigidity of the X-axis through guides on two levels. This is particularly important when heavy workpieces cannot be clamped centrally on the rotary table and this is rotated.

Mikron HPM series is universal

+ Predestined for processing with high cutting forces

+ Both the swivel axis and the rotary axis can be clamped

+ Due to the high stability, the tool life is extended

+ The water cooling for the table drive guarantees reliably high precision over long machining times.

State-of-the-art Swiss motor spindles, directly driven rotary and swivel axes and a stable machine body offer the best conditions for economical and precise production with modern tools.

Used for heavy-duty roughing to precise finishing

Highlights

+ Direct measurement system

+ Water cooling

+ C-axis with clamping

+ High loading weight

+ High torque

15000 rpm ISO-B40 / HSK-A63

The ideal spindle for universal use

The facts

+ Vector control for full torque in the deepest Area

+ Highly stable ceramic hybrid spindle bearing

+ Spindle jacket cooling by means of a controlled coolant circuit for constant temperatures throughout the working time

+ Integrated "smart machine" sensors

Your benefit

+ Maximum precision and high cutting performance

+ Shorter acceleration phases

+ High torque at low speeds

+ Tapping without compensating chuck

The tool magazine has its own control panel to call up the desired tool.

No tools are required to remove and load the tool holder.

The tools are changed by using a double gripper.

The tools can be loaded and unloaded with the release.

In order to observe the machining process during horizontal machining as well, the control panel is swiveled from the front of the machine to the side window or near the tool magazine.

Accessories (according to owner):

2 as new tool cabinets with approx. 180 tapers

3 Allmatic NC clamps 125 mm with accessories

1 new compressed air cylinder for tool changer

Approx. 25 tool holders

Extensions and solid carbide tools approx. 200 pieces

Construction elements 150 mm and much more….

Complete with:

5-Axis simultaneous working

Direct measurement system X,Y,Z,C,B Axes

Direct drive to table rotational axis C

Direct drive to milling head swivelling axis B

Coolant unit and large coolant tank

High pressure coolant through the spindle 40 bar

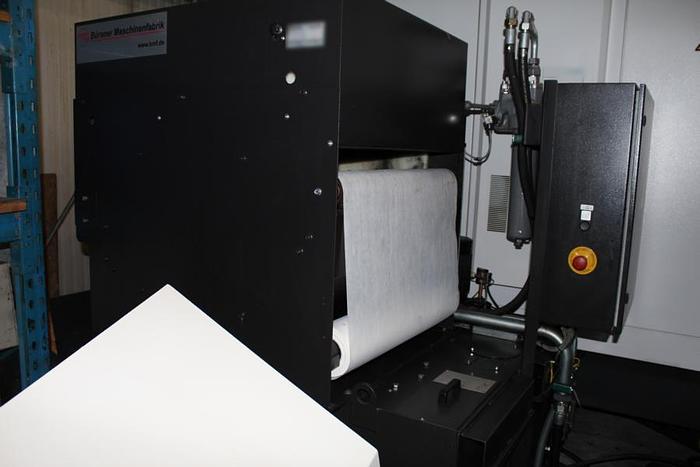

Coolant filtration unit

Renishaw parts probing

Chip conveyor

Chip bin

Large complement of tooling

All clamping equipment

The machine has been well cared for and maintained

The machine can be inspected and tested under power

FOR THE CUSTOMER WE CAN CARE FOR TRANSPORT AS WELL.

Specifications

| Manufacturer | MIKRON |

| Model | HPM 1350U |

| Year | 2008 |

| Condition | Used |